Characteristics of The Z Belt

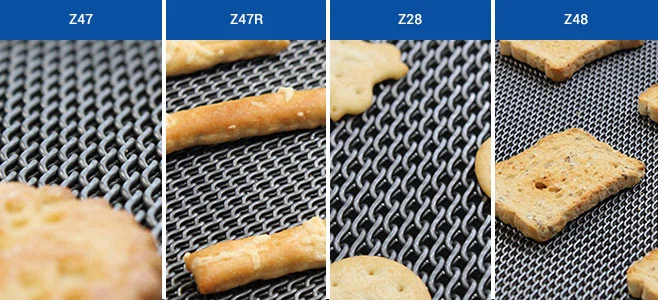

We mainly offer 4 types of Z belts depending on the technical characteristics required. These being weight, size, thickness, thermal inertia, and air circulation through the mesh.

All Z belts are made following strict quality criteria. The edges are looped to make the belt more flexible and improve contact with the drive drums. The finishing of the edges reduces the risk of damage to the belt by the lateral guides or the blades of the ovens.

The manufacturing method ensures perfect alignment of the wire and a wider space between the meshes for equivalent resistance. This is essential for allowing customers to bake in their ovens quickly and evenly while keeping the Z belt clean.

Z47 this belt is renowned for large, high-performance equipment with speeds up to 30m/min. The space between the meshes allows excellent air circulation during cooking.

Z47R – is a version of the Z47 belt with increased resistance to tearing, providing a longer belt life or intensive use. This belt does however require a higher baking temperature than the Z47.

Z28 – this belt allows the oven temperature to be lowered for the purpose of cost savings. The wire diameter is smaller, and high temperatures should therefore be avoided.

Z48 – specially designed for baking rusks and hard biscuits, the Z48 belt has wide mesh for optimised air circulation.