When installing a new belt, or belt section, our highly trained service specialists, use patented machinery to align the belt prior to welding. Once the belt is welded and the seam dressed, our specialists carry out tests to ensure the belt thickness in the weld area meets our tight tolerances. our specialists ensure that the drums, or sheaves at either end of the line are correctly aligned, prior to running the belt to ensure the belt is tracking correctly, tweaking where necessary until any belt deviation is eliminated. The line is then handed back over to the end user.

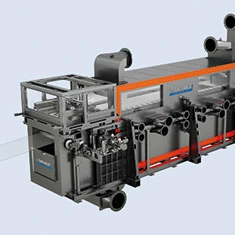

Furthermore, PACE conveyor machinery, such as cooling conveyors or drying lines, are built with integrated belt tracking solutions to maintain alignment and reduce edge wear. For systems with tighter tolerances or higher operating speeds, additional tracking rollers or PACEMatic systems can be incorporated. These can also be retrofitted to legacy machinery to reduce belt tracking issues.