CLIENT BRIEF:

Following a severe oven fire, the fire brigade poured cold liquid throughout one of the ovens to stop the fire. Unfortunately, this destroyed the oven band. The cold liquid poured on the hot metal caused the belt to warp and contract beyond repair. We were called out to install the spare belt we held at our facility on behalf of the customer. We were able attend site within 24 hours to respond and arrange the installation of a new belt, keeping downtime to a minimum.

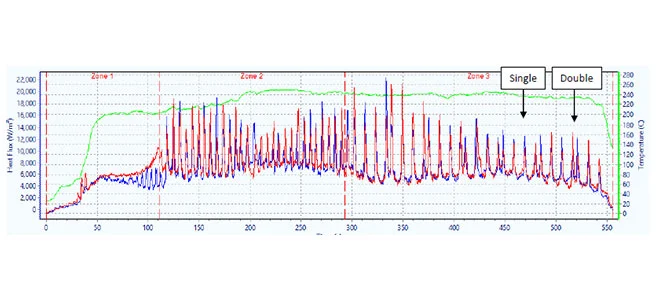

Following the installation of the oven the oven band, the customer was seeing issues with the consistency of the product, we were therefore asked to perform several service interventions and asses the route cause. Due to our internal protocols and subsequent checks, we could guarantee that the band was correctly aligned and the drums and belt touching elements were all functioning and set up correctly. We determined that thermal profiling of the oven would be the most accurate method to assess inside the oven. Specially designed cameras and thermal profiling equipment were installed throughout the oven chamber to collate as much data as possible. This data was then analysed to ascertain thermal performance and patterns.

The report revealed that the route cause was several plenums within the oven which had been damaged in the fire. We then replaced these, assisted by our colleagues. Subsequently, product consistency has improved, and the oven is performing well again.