Rubber & Plastics

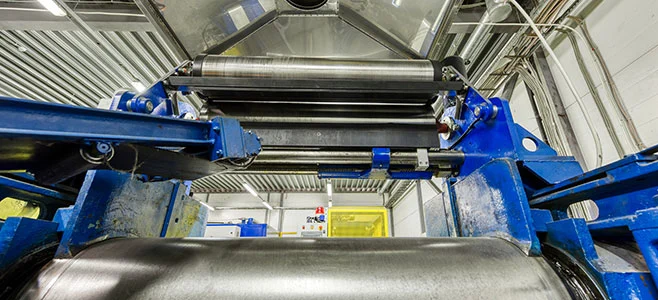

Berndorf Band manufactures steel belts that deliver the specific properties needed for the production of rubber and plastic sheet products using, for instance, rotocure machines. Given the extreme loads of stress to which they are subjected, the belts need to feature a design that ensures maximum strength and tolerance as well as a long lifetime. Taking full advantage of their experience in manufacturing steel belts, Berndorf Band has found the perfect material in NC52.6 and discovered the special properties the weld seam of the belt must possess. Both the martensitic materials and the spiral weld seam satisfy even the highest standards, guaranteeing product quality that is second to none. Steel belt cooling conveyors are also used in the production of such materials.

Highlights

• Unrivalled surface quality

• Industry-specific weld seam options

• Outstanding flatness of the weld seam and the belt

• Exceptional operating characteristics

• Superior belt life